| SPI Finish | Description | Typical Applications Surface | Roughness (Ra µm) |

|---|---|---|---|

| SPI A-1 | Grade #3, 6000 Grit Diamond Buff | High polish or transparent parts, optically clear | 0.012 - 0.025 |

| SPI A-2 | Grade #6, 3000 Grit Diamond Buff | High polish or transparent parts | 0.025 - 0.050 |

| SPI A-3 | Grade #15, 1200 Grit Diamond Buff | High-to-medium polish parts, non-optical lenses | 0.050 - 0.100 |

| SPI B-1 | 600 Grit Paper | Medium polish parts | 0.05 - 0.10 |

| SPI B-2 | 400 Grit Paper | Medium polish parts | 0.10 - 0.15 |

| SPI B-3 | 320 Grit Paper | Medium - low polish parts | 0.28 - 0.32 |

| SPI C-1 | 600 Stone | Low polish parts | 0.35 - 0.40 |

| SPI C-2 | 400 Stone | Low polish parts | 0.45 - 0.55 |

| SPI C-3 | 320 Stone | Low polish parts | 0.63 - 0.70 |

| SPI D-1 | Dry Blast Glass Bead | Satin finish | 0.80 - 1.00 |

| SPI D-2 | Dry Blast #240 Oxide | Dull finish | 1.00 - 2.80 |

| SPI D-3 | Dry Blast #24 Oxide | Dull finish | 3.20 - 18.00 |

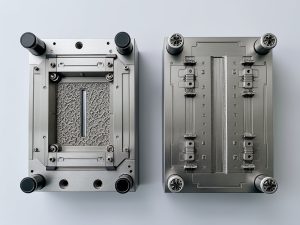

Plastic Injection Molding

CAPABILITIES

Plastic Injection Molding

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 1 business day.

Our Injection Molding Process

Injection molding is the most economical method for mass-producing plastic parts. This process involves injecting molten plastic into a mold, where it solidifies before being ejected. This cycle repeats rapidly, allowing the cost of the mold to be spread across hundreds or thousands of parts, reducing the cost per unit to just a few dollars or less. Using the same mold for each part ensures consistent quality across all units. Injection molding offers the widest range of materials, colors, finishes, and surface textures, surpassing the options available through CNC machining or 3D printing. Long Shen's custom plastic molding service provides on-demand prototyping and production molding. We prioritize a customer-first approach, ensuring we deliver the perfect injection molding solution to meet your needs.

Design Validation and Production

Steel tooling with rapid lead times and no minimum order quantities—ideal for prototyping, design validation, and bridge production.

Overmolding

For applications such as buttons, grips, or seals, overmold rubber or silicone onto an existing plastic part.

Insert Molding

Mold plastic around a preformed insert, often metal-threaded, to create components with integrated metal parts.

Plastic Injection Molding Materials

Can mold any commercially available thermoplastic. Please reach out with your specific resin needs.

Plastic Injection Molding Finishing Option

SPI Finishes (Society of the Plastics Industry):

MT (Moldtech):

Common Mold-Tech Injection Molding Finishes

| Mold-Tech Serial Number | Texture Depth (inch) | Application | Minimum Draft |

|---|---|---|---|

| MT-11010 | 0.001" | Dull matte finish | 1.5° |

| MT-11020 | 0.0015" | Coarse matte finish | 2.25° |

| MT-11030 | 0.002" | Coarse matte finish | 3° |

VDI (Verein Deutscher Ingenieure):

Common VDI Injection Molding Finishes

| VDI Value | Description | Applications | Surface Roughness (Ra µm) |

|---|---|---|---|

| VDI 12 | 600 Stone | Low polish parts | 0.40 |

| VDI 15 | 400 Stone | Low polish parts | 0.56 |

| VDI 18 | Dry Blast Glass Bead | Satin finish | 0.80 |

| VDI 21 | Dry Blast # 240 Oxide | Dull finish | 1.12 |

| VDI 24 | Dry Blast # 240 Oxide | Dull finish | 1.60 |

| VDI 27 | Dry Blast # 240 Oxide | Dull finish | 2.24 |

| VDI 30 | Dry Blast # 24 Oxide | Dull finish | 3.15 |

| VDI 33 | Dry Blast # 24 Oxide | Dull finish | 4.50 |

| VDI 36 | Dry Blast # 24 Oxide | Dull finish | 6.30 |

| VDI 39 | Dry Blast # 24 Oxide | Dull finish | 9.00 |

| VDI 42 | Dry Blast # 24 Oxide | Dull finish | 12.50 |

| VDI 45 | Dry Blast # 24 Oxide | Dull finish | 18.00 |

YS (Yick Sang)

Require YS Finish? Contact us, and we will look into accommodating you to meet your requirements!

Plastic Secondary Operations Processes

All finishes meet SPI standards

Heat Staking

Heating plastic to reform it and insert a component (e.g., a threaded insert).

Laser Engraving

Engraving text or a design with a laser.

Pad Printing

Applying an ink-based, 2D design to a 3D surface

Painting

Applying primer, topcoat, EMI (copper) paint, in both standard and Pantone colors.

Ultrasonic Plastic Welding

Joining or reforming thermoplastics with a high-frequency welder

How it Works

1. Submit Your Designs

Upload your 3D CAD and 2D technical drawings to our secure platform.

2. Receive a Quote

Configure your projects in our quote-to-order system and get pricing within one day.

3. Review Your T1 Samples

During the trial phase, view the T0 sampling and receive T1 samples within 2-3 weeks for review before production begins.

4. Order Parts

After sample approval, production starts with an average lead time of 4-7 business days.

5. Begin Production

Utilize our mold library to select and order your parts.

6. Ready to Begin?