When it comes to sustainable water management, water conservation in manufacturing plays a crucial role. By implementing water efficiency measures, manufacturers can significantly reduce their water consumption, save valuable resources, and protect water quality. In this article, we will explore the importance of water conservation in the manufacturing industry and discuss effective strategies and practices for achieving sustainable water use.

Key Takeaways:

- Water conservation in manufacturing is essential for sustainable water management

- Implementing water efficiency measures helps reduce operating costs and protect water quality

- Strategies include corporate water conservation, water recycling, and process optimization

- Upgrading to water-efficient equipment and fixtures and involving employees are crucial

- Monitoring and evaluating water conservation efforts is essential for continuous improvement

Importance of Water Conservation in Manufacturing

In the manufacturing industry, water conservation plays a crucial role in promoting water efficiency, reducing industrial water usage, and achieving eco-friendly manufacturing practices. By implementing sustainable water management strategies, manufacturers can optimize their operations, minimize environmental impact, and contribute to a more sustainable future.

Eco-friendly manufacturing practices focus on reducing water consumption and waste generation in production processes. This includes adopting innovative technologies and techniques that promote efficient water use, such as:

- Water-efficient equipment and fixtures

- Process optimization for water conservation

- Effective water management in cooling systems

- Water recycling and waste treatment

By incorporating these practices, manufacturers can achieve significant reductions in water usage and contribute to the preservation of water resources.

The Benefits of Water Conservation in Manufacturing

Implementing water conservation measures in manufacturing facilities offers numerous benefits, including:

- Reduced operating costs: By minimizing water consumption and optimizing water use, manufacturers can lower their water bills and decrease associated operating expenses.

- Resource conservation: Efficient water management helps conserve precious freshwater resources, ensuring their availability for future generations.

- Environmental protection: By reducing industrial water usage and waste generation, manufacturers can minimize their ecological footprint and contribute to a cleaner, healthier environment.

- Sustainable manufacturing: Water conservation aligns with sustainable manufacturing practices, promoting responsible resource use and supporting the transition to a circular economy.

“Water conservation in manufacturing is not only a responsibility but also an opportunity for businesses to improve their efficiency, reduce costs, and demonstrate their commitment to environmental sustainability.”

Implementing Water Conservation Practices

Manufacturers can adopt various water conservation practices to achieve eco-friendly manufacturing processes. These include:

| Water Conservation Practice | Description |

|---|---|

| Implementing water-efficient equipment and fixtures | Upgrading to high-efficiency plumbing fixtures and using water-saving equipment can significantly reduce water consumption in manufacturing facilities. Regular equipment cleaning also helps optimize water use. |

| Optimizing processes for water conservation | By improving operational efficiency, reducing waste generation, and reusing process water, manufacturers can minimize water consumption and maximize resource efficiency. |

| Managing water in cooling systems | Proper treatment of cooling tower water, implementing evaporation reduction techniques, and preventing water loss through maintenance and leak repairs can contribute to significant water savings. |

| Implementing water recycling and waste treatment systems | By treating wastewater, implementing water recycling systems, and maintaining efficient effluent and sewage treatment plants, manufacturers can reduce water consumption and minimize the environmental impact of waste. |

Engaging employees and raising awareness about water conservation is also key to the success of these initiatives. By fostering a culture of responsible water use and encouraging employee involvement, manufacturers can further enhance their water conservation efforts.

Water Conservation Strategies in Manufacturing

Implementing effective water conservation strategies in manufacturing is crucial for minimizing water consumption and reducing the environmental impact. By adopting corporate water conservation strategies, promoting efficient water use in production processes, and incorporating water recycling systems in factories, manufacturers can contribute to a more sustainable water management approach.

The Benefits of Corporate Water Conservation Strategies

Implementing corporate water conservation strategies is a proactive approach that can help manufacturers achieve significant water savings. These strategies involve setting clear water reduction goals, implementing water-efficient technologies, and establishing water monitoring and reporting systems. By making water conservation a priority, manufacturers can not only reduce costs but also enhance their sustainability credentials and strengthen their business reputation.

Promoting Efficient Water Use in Production Processes

Efficient water use in production processes is essential for minimizing water consumption without compromising productivity. Manufacturers can implement various measures to optimize water use, such as:

- Installing water-efficient equipment and fixtures

- Implementing process optimization techniques

- Eliminating water leaks and minimizing water waste

- Promoting employee awareness and responsibility in water conservation

These measures not only lead to water savings but can also improve operational efficiency and reduce production costs.

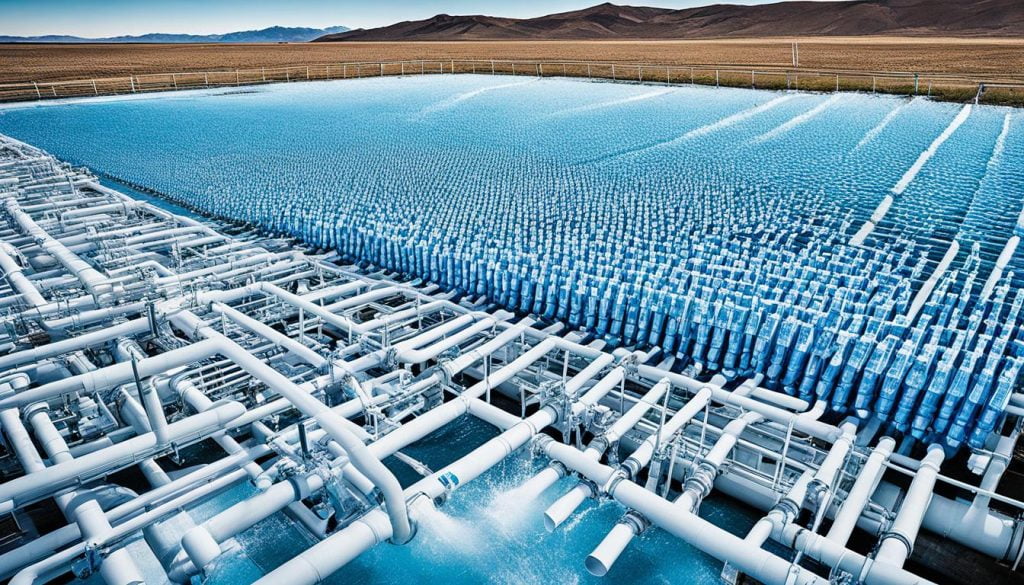

Incorporating Water Recycling Systems in Factories

Water recycling is an effective strategy for reducing the overall demand for freshwater in manufacturing processes. By treating and reusing wastewater within the factory, manufacturers can conserve water resources and minimize the discharge of pollutants into the environment. Implementing water recycling systems, such as advanced filtration technologies and closed-loop systems, can significantly reduce water consumption and contribute to sustainable water management.

| Water Conservation Strategy | Description |

|---|---|

| Corporate Water Conservation Strategies | Implementation of water reduction goals, water-efficient technologies, and monitoring systems. |

| Efficient Water Use in Production Processes | Installation of water-efficient equipment, process optimization, leak prevention, and employee engagement in water conservation. |

| Water Recycling in Factories | Treatment and reuse of wastewater within the factory through advanced filtration technologies and closed-loop systems. |

By adopting corporate water conservation strategies, promoting efficient water use in production, and incorporating water recycling systems, manufacturers can minimize water consumption, reduce their environmental footprint, and contribute to a more sustainable future.

Water-Efficient Equipment and Fixtures

Upgrading to water-efficient equipment and fixtures is an effective way to conserve water in manufacturing. By replacing outdated systems with high-efficiency plumbing fixtures, such as toilets and faucets, you can significantly reduce water consumption.

High-efficiency plumbing fixtures are designed to maximize water savings without compromising performance. These fixtures use advanced technologies, such as dual-flush toilets and aerated faucets, to minimize water usage while providing the same level of functionality.

For example, upgrading to a high-efficiency toilet can save up to 20% more water compared to traditional toilets. This simple switch can have a substantial impact on overall water consumption in your manufacturing facility.

Additionally, using water-saving equipment in your production processes can further optimize water use. Look for equipment that is specifically designed to minimize water consumption, such as efficient cooling systems, water-efficient pumps, and closed-loop systems.

To ensure the continued efficiency of your water-saving equipment, it is essential to implement proper equipment cleaning practices. Regular maintenance and cleaning can prevent clogs, leaks, and other issues that can lead to unnecessary water waste.

“Using high-efficiency plumbing fixtures and water-saving equipment can significantly reduce water consumption in manufacturing facilities, contributing to a more sustainable and environmentally friendly operation.”

The Benefits of Water-Efficient Equipment and Fixtures

There are numerous benefits to upgrading to water-efficient equipment and fixtures in your manufacturing facility:

- Significant water savings: High-efficiency plumbing fixtures and water-saving equipment can help you achieve substantial reductions in water consumption, leading to cost savings on water bills.

- Environmental impact: By conserving water, you can minimize your facility’s environmental footprint and contribute to a more sustainable future.

- Compliance with regulations: Many jurisdictions have water conservation regulations in place. Upgrading to water-efficient equipment and fixtures can help ensure compliance with these regulations.

- Improved reputation: Demonstrating a commitment to sustainability and responsible resource management can enhance your company’s reputation and attract environmentally conscious partners and customers.

By investing in high-efficiency plumbing fixtures, water-saving equipment, and proper equipment cleaning practices, you can contribute to water conservation efforts while optimizing your manufacturing processes.

| Water-Efficient Equipment | Water Savings |

|---|---|

| High-efficiency toilets | Up to 20% more water saved compared to traditional toilets |

| Aerated faucets | Up to 50% water savings |

| Efficient cooling systems | Reduced water consumption through optimization |

| Water-efficient pumps | Reduction in water usage |

| Closed-loop systems | Minimized water waste through recycling |

Upgrading your equipment and fixtures not only saves water but also enhances your overall manufacturing efficiency. By embracing water-saving technologies and practices, you can make a positive impact on both your bottom line and the environment.

Process Optimization for Water Conservation

Optimizing manufacturing processes plays a crucial role in conserving water resources. By improving operational efficiency, reducing waste generation, and implementing process water reuse systems, manufacturers can significantly minimize water consumption. Continuous evaluation and optimization of processes are key to achieving sustainable water management practices and operational excellence.

Improving Operational Efficiency

Enhancing operational efficiency not only leads to cost savings but also promotes water conservation. Through the implementation of lean manufacturing principles and advanced technologies, such as automation and data analysis, manufacturers can streamline production processes and reduce water usage. By optimizing equipment utilization and minimizing downtime, operational efficiency can be maximized, resulting in significant water savings.

Reducing Waste Generation

Reducing waste generation is a fundamental step towards water conservation. By implementing waste reduction strategies, such as lean manufacturing practices, material substitution, and process optimization, manufacturers can minimize water usage throughout the production cycle. By identifying areas of waste and implementing corrective actions, manufacturers can achieve substantial water savings and contribute to a more sustainable manufacturing environment.

Implementing Process Water Reuse Systems

Process water reuse systems offer a sustainable solution to reduce water consumption in manufacturing. By treating and reusing process water that would otherwise be discarded as wastewater, manufacturers can minimize their reliance on freshwater sources. Implementing advanced filtration and purification technologies ensures the quality and safety of reused process water, allowing manufacturers to achieve water savings without compromising product quality or process integrity.

By continuously evaluating and optimizing processes, manufacturers can achieve significant water savings, reduce operational costs, and enhance their environmental performance.

As manufacturers strive for operational excellence, the importance of process optimization for water conservation cannot be overstated. By improving operational efficiency, reducing waste generation, and implementing process water reuse systems, manufacturers can contribute to a more sustainable and water-efficient future.

Water Conservation in Cooling Systems

Cooling systems in manufacturing facilities can be major water consumers. However, by implementing effective water conservation practices, such as proper cooling tower water treatment, optimizing water evaporation reduction, and preventing water loss, significant progress can be made.

Regular maintenance and repair of leaks in cooling systems can help minimize water loss and ensure efficient operation. The use of drift eliminators can also contribute to water conservation efforts by reducing the amount of water lost through evaporation.

“Proper treatment of cooling tower water is essential for maintaining system efficiency and reducing water consumption.”

One effective approach to conserve water in cooling systems is to invest in cooling tower water treatment. By treating the water used in cooling towers, manufacturers can prevent the buildup of scale, corrosion, and biological contamination. This not only extends the lifespan of the equipment but also enhances system efficiency, reducing water consumption in the long run.

Additionally, optimizing water evaporation reduction techniques can significantly minimize water loss in cooling systems. Installing covers on open cooling towers or employing evaporative condensers can help reduce water evaporation rates, thereby conserving water resources.

Benefits of Water Conservation in Cooling Systems

- Reduced water consumption and associated costs

- Increased operational efficiency

- Lower environmental impact

- Enhanced equipment lifespan

The table below provides an overview of the essential elements for water conservation in cooling systems:

| Water Conservation Measures | Description |

|---|---|

| Cooling Tower Water Treatment | Implementing proper treatment techniques to maintain system efficiency and minimize water consumption. |

| Water Evaporation Reduction | Employing techniques such as covers on open cooling towers or evaporative condensers to reduce water evaporation rates. |

| Preventing Water Loss | Regular maintenance, repair of leaks, and the use of drift eliminators to prevent water loss in cooling systems. |

Water Management in Waste Treatment

Proper water management in waste treatment is essential for water conservation in manufacturing. By implementing effective wastewater treatment systems, recycling water, and maintaining efficient effluent and sewage treatment plants, manufacturers can significantly reduce water consumption and minimize the environmental impact of industrial waste.

Implementing Wastewater Treatment Systems

One of the key aspects of water management in waste treatment is the implementation of wastewater treatment systems. These systems are designed to remove pollutants and contaminants from wastewater, ensuring that it meets the required standards before being discharged or reused.

Wastewater treatment involves several processes, such as primary treatment, secondary treatment, and tertiary treatment. During primary treatment, solid particles and large debris are removed through physical processes like sedimentation and filtration. Secondary treatment focuses on biological processes that break down organic matter and remove dissolved pollutants. Tertiary treatment further refines the water quality through additional filtration and disinfection processes.

Implementing advanced and efficient wastewater treatment systems can help manufacturers maintain regulatory compliance, protect local water sources, and reduce the overall demand for freshwater resources.

Recycling Water

Another crucial aspect of water management in waste treatment is water recycling. Instead of discharging treated wastewater into water bodies, manufacturers can recycle it for various non-potable applications within their facilities.

Recycled water can be used for purposes like irrigation, cooling tower operations, and toilet flushing. By utilizing treated wastewater for these applications, manufacturers can reduce their reliance on freshwater sources, conserve water, and lower their operational costs.

Maintaining Effluent and Sewage Treatment Plants

Maintaining effluent and sewage treatment plants is essential for the effective management of wastewater. Regular maintenance and monitoring of these plants ensure their optimal performance, preventing any potential issues that may result in water contamination or inefficiency.

Effluent treatment plants (ETPs) are responsible for treating industrial wastewater generated from manufacturing processes. These plants employ various treatment technologies to remove pollutants and make the water suitable for discharge or reuse.

On the other hand, sewage treatment plants (STPs) are designed to treat domestic wastewater from facilities like restrooms and kitchens. STPs incorporate primary, secondary, and tertiary treatment processes to remove contaminants and produce treated water.

Proper maintenance, regular inspection, and adherence to operational guidelines are essential for the smooth functioning of effluent and sewage treatment plants, minimizing the environmental impact of wastewater discharge.

| Treatment Plant Type | Treatment Processes | Main Functions |

|---|---|---|

| Effluent Treatment Plant (ETP) | Physical, Biological, and Chemical Treatment | Treats industrial wastewater to remove pollutants and contaminants, ensuring compliance with regulations |

| Sewage Treatment Plant (STP) | Primary, Secondary, and Tertiary Treatment | Treats domestic wastewater to remove impurities and produce treated water for safe disposal or reuse |

By implementing wastewater treatment systems, recycling water, and maintaining effluent and sewage treatment plants, manufacturers can effectively manage water in waste treatment, contributing to water conservation efforts in the manufacturing industry.

Employee Education and Involvement

Employee education and involvement play a crucial role in promoting water conservation in manufacturing. By creating awareness about the importance of water conservation, encouraging employees to contribute innovative solutions, and providing training on water-saving practices, companies can foster a culture of responsible water use within the organization.

Water conservation awareness programs can be implemented to educate employees about the significance of conserving water resources. These programs can include informative sessions, presentations, and workshops that highlight the environmental and economic benefits of water conservation. Engaging employees in discussions about water-saving initiatives cultivates a sense of responsibility and empowers them to actively contribute to conservation efforts.

Furthermore, companies can encourage employees to develop and implement water-saving innovations specific to their roles and processes. By leveraging the diverse expertise within the workforce, organizations can discover creative solutions for optimizing water use and minimizing waste. Employee-driven innovations can range from process improvements and equipment modifications to the implementation of water recycling systems.

To ensure effective employee engagement, companies can establish clear communication channels for sharing ideas, suggestions, and success stories related to water conservation. These channels can include online platforms, suggestion boxes, or dedicated email addresses. Recognizing and rewarding employees’ contributions and achievements in water conservation further reinforces their commitment to sustainable practices.

Benefits of Employee Education and Involvement

Empowering employees with knowledge and involving them in water conservation initiatives can yield several benefits:

- Enhanced sense of ownership and responsibility towards water conservation

- Increased employee satisfaction and morale due to active participation in sustainability efforts

- Potential for continuous improvement as employees contribute new ideas and solutions

- Improved operational efficiency and cost savings through optimized water use

- Positive impact on the company’s reputation and brand image as a socially responsible organization

Employee Training on Water-Saving Practices

Providing comprehensive training to employees on water-saving practices is essential for successful water conservation implementation. This training can cover topics such as:

- The importance of water conservation and its impact on the environment and business sustainability

- Best practices for reducing water consumption in daily operations

- Proper maintenance and operation of water-efficient equipment and fixtures

- Identification and reporting of water leaks or other inefficiencies

- Understanding the company’s water management goals and targets

By equipping employees with the necessary knowledge and skills, companies can create a workforce that actively contributes to water conservation efforts and helps achieve long-term sustainability goals.

Monitoring and Evaluation of Water Conservation Efforts

Monitoring and evaluating your water conservation efforts is essential to ensure the effectiveness of your strategies and identify areas for improvement. By conducting regular water consumption audits, tracking performance metrics, and implementing a continuous improvement process, you can optimize your water conservation initiatives and achieve long-term sustainability.

Water Consumption Audit

A water consumption audit involves a detailed assessment of your water usage throughout your manufacturing processes. It helps you identify the specific areas where water is being consumed and determine the volume of water consumed in each process. By understanding your water consumption patterns, you can identify potential areas for optimization and implement targeted conservation measures.

Performance Tracking

Tracking and analyzing performance metrics related to water consumption is crucial for monitoring your progress and identifying any deviations from your targets. By measuring and comparing key indicators such as water usage per unit of production, water loss rates, and water recycling rates, you can identify areas of inefficiency and implement corrective actions.

Continuous Improvement

Implementing a continuous improvement process enables you to continually enhance your water conservation efforts. By identifying opportunities for optimization, seeking innovative solutions, and regularly reviewing and updating your water management strategies, you can achieve sustained improvements in water efficiency and conservation. Encouraging employee involvement and fostering a culture of innovation can also drive continuous improvement initiatives.

Table: Key Performance Metrics for Water Conservation

| Performance Metric | Description |

|---|---|

| Water usage per unit of production | Measures the amount of water consumed for each unit of output. Helps identify inefficiencies and benchmark performance. |

| Water loss rates | Tracks the percentage of water lost due to leaks, evaporation, or other factors. A high loss rate indicates potential areas for water conservation. |

| Water recycling rates | Measures the percentage of water that is recycled or reused in the manufacturing processes. Higher recycling rates indicate efficient water management. |

| Cost savings from water conservation | Quantifies the financial benefits of implementing water conservation measures. Helps evaluate the return on investment and prioritize future initiatives. |

| Employee engagement and innovation | Evaluates the level of employee involvement and the implementation of innovative water-saving ideas. Highlights the importance of a collaborative approach to water conservation. |

By regularly monitoring and evaluating your water conservation efforts, you can drive ongoing improvements in water efficiency, reduce costs, and contribute to a more sustainable future.

Conclusion

Water conservation plays a vital role in sustainable manufacturing and efficient water management. By implementing effective strategies, optimizing processes, and engaging employees, manufacturers can make a significant impact on reducing water usage and minimizing their environmental footprint. The future of water management depends on the collective efforts of businesses to prioritize water conservation in their operations.

Through the implementation of water conservation measures, manufacturers can not only benefit from reduced operating costs but also contribute to a more sustainable future. By emphasizing the importance of water conservation in the manufacturing industry, we can ensure the long-term preservation of water resources.

As we move forward, it is crucial for manufacturers to continue prioritizing water conservation as an integral part of their sustainable manufacturing practices. By embracing innovative technologies and promoting water-saving initiatives, we can pave the way for a more responsible and efficient use of water resources, not only within the manufacturing sector but also in our broader communities.

FAQ

Why is water conservation important in the manufacturing industry?

Water conservation is important in the manufacturing industry to promote water efficiency, reduce industrial water usage, and minimize the environmental impact of production processes.

What are some strategies for water conservation in manufacturing?

Some strategies for water conservation in manufacturing include implementing corporate water conservation strategies, promoting efficient water use in production processes, and incorporating water recycling systems in factories.

How can water-efficient equipment and fixtures contribute to water conservation in manufacturing?

Upgrading to water-efficient equipment and fixtures, such as high-efficiency plumbing fixtures and water-saving equipment, can significantly reduce water consumption and optimize water use in manufacturing processes.

What is process optimization, and how does it contribute to water conservation?

Process optimization involves improving operational efficiency, reducing waste generation, and implementing process water reuse systems to minimize water consumption in manufacturing.

How can water conservation be achieved in cooling systems?

Water conservation in cooling systems can be achieved through proper cooling tower water treatment, optimizing water evaporation reduction techniques, and preventing water loss through regular maintenance and the use of drift eliminators.

What is the importance of water management in waste treatment for water conservation in manufacturing?

Proper water management in waste treatment, including implementing wastewater treatment systems, recycling water, and maintaining effluent and sewage treatment plants, can help reduce water consumption and minimize the environmental impact of industrial waste.

How can employee education and involvement contribute to water conservation in manufacturing?

Employee education and involvement are key factors in promoting water conservation in manufacturing. Creating awareness about the importance of water conservation, encouraging employees to contribute innovative solutions, and providing training on water-saving practices can create a culture of responsible water use within the organization.

Why is it important to monitor and evaluate water conservation efforts in manufacturing?

Monitoring and evaluating water conservation efforts is crucial to track progress, identify areas for improvement, and optimize water conservation initiatives in manufacturing.

What is the overall impact of water conservation in manufacturing?

Water conservation in manufacturing has a significant impact on sustainable water management, efficient resource utilization, and the reduction of environmental footprint, contributing to a more sustainable future.