Did you know that industrial automation and AI technologies are projected to drive a $4.8 trillion growth in the global manufacturing industry by 2026? As the manufacturing sector continues to rapidly evolve, so does the importance of prioritizing safety measures to protect the well-being of employees and enhance operational efficiency.

Key Takeaways:

- Industrial automation and AI technologies are driving significant growth in the global manufacturing industry.

- Prioritizing safety measures is crucial for protecting employees and optimizing operational efficiency.

- Future trends in manufacturing safety include workplace safety technology, predictive maintenance, smart manufacturing solutions, digital transformation in safety management, AI integration, IoT applications, and machine learning for occupational safety.

- These trends revolutionize safety management by improving data collection, analysis, and real-time monitoring.

- Manufacturers must embrace these trends to stay competitive and create safer work environments for their workforce.

5G and Edge Computing

5G and edge computing are revolutionizing the manufacturing industry by enabling faster and more reliable wireless connectivity. With 5G technology, data can be transferred seamlessly, allowing for real-time monitoring and analysis. This ensures that manufacturers can gather and process data instantaneously, optimizing their operations and enhancing safety measures.

One of the key advantages of 5G and edge computing is the ability to enable remote monitoring. By connecting safety sensors and devices wirelessly, manufacturers can continuously monitor their facilities from a distance. This not only eliminates the need for manual checks but also provides real-time insights into potential hazards or safety concerns.

Edge computing plays a crucial role in reducing latency and enabling immediate actions in hazardous environments. With traditional cloud computing, there can be delays in data analysis and response due to the round-trip time from the device to the cloud and back. However, with edge computing, the computing power is brought closer to the front lines, reducing latency and allowing for immediate actions to be taken to address safety risks.

In a manufacturing setting, the ability to take immediate actions based on real-time data is critical for ensuring the safety of workers and preventing accidents. By leveraging 5G and edge computing, manufacturers can identify and respond to safety concerns in real-time, mitigating risks and creating a safer work environment.

“5G and edge computing are transforming the manufacturing industry, enabling faster wireless connectivity, real-time data transfer, remote monitoring, and immediate actions to address safety risks.”

By harnessing the power of 5G and edge computing, manufacturers can take advantage of the benefits of wireless connectivity, real-time data transfer, remote monitoring, and immediate actions. These advancements in technology are revolutionizing manufacturing safety, enhancing efficiency, and ensuring the well-being of workers.

Digitization and Automation

Digitization and automation are driving significant advancements in manufacturing safety, transforming the way safety procedures are implemented and monitored. These technological innovations enable efficient data gathering and the automation of critical processes, resulting in improved safety measures and increased worker focus. With the integration of advanced technologies, manufacturing facilities can achieve higher efficiency gains while ensuring a safer work environment.

One of the key benefits of digitization and automation is the ability to collect and analyze data without human intervention. Through the implementation of sensors and IoT devices, real-time data can be gathered, providing accurate insights into the conditions and operations within the facility. This data-driven approach allows for more informed decision-making regarding safety procedures and enables proactive measures to be taken to prevent potential hazards.

Automation plays a pivotal role in reducing the reliance on manual work and streamlining redundant tasks. By automating processes that were traditionally performed by workers, such as repetitive inspections or routine maintenance, employees can focus on more complex and value-adding activities. This not only enhances the efficiency of manufacturing operations but also improves worker satisfaction and engagement. With automated systems in place, manufacturing facilities can optimize maintenance schedules, ensuring the proper functioning of equipment and reducing the risk of accidents.

Furthermore, safety shut-off procedures can be integrated into automated systems, providing immediate responses in the event of an emergency. This ensures the safety of workers by swiftly shutting down equipment or initiating safety protocols to mitigate potential risks. The combination of digitization and automation enhances the overall safety measures within manufacturing facilities, creating a secure environment for employees.

“Digitization and automation in manufacturing safety enable data-driven decision-making, efficiency gains, and enhanced worker focus.”

The integration of digitization and automation in manufacturing safety brings about several benefits. By streamlining data gathering, automating processes, and improving maintenance schedules and safety shut-off procedures, manufacturing facilities can achieve greater efficiency gains while ensuring the well-being of their employees. These advancements in technology not only improve the overall safety measures but also empower manufacturers to stay competitive in the rapidly evolving manufacturing industry.

Robotics and AI

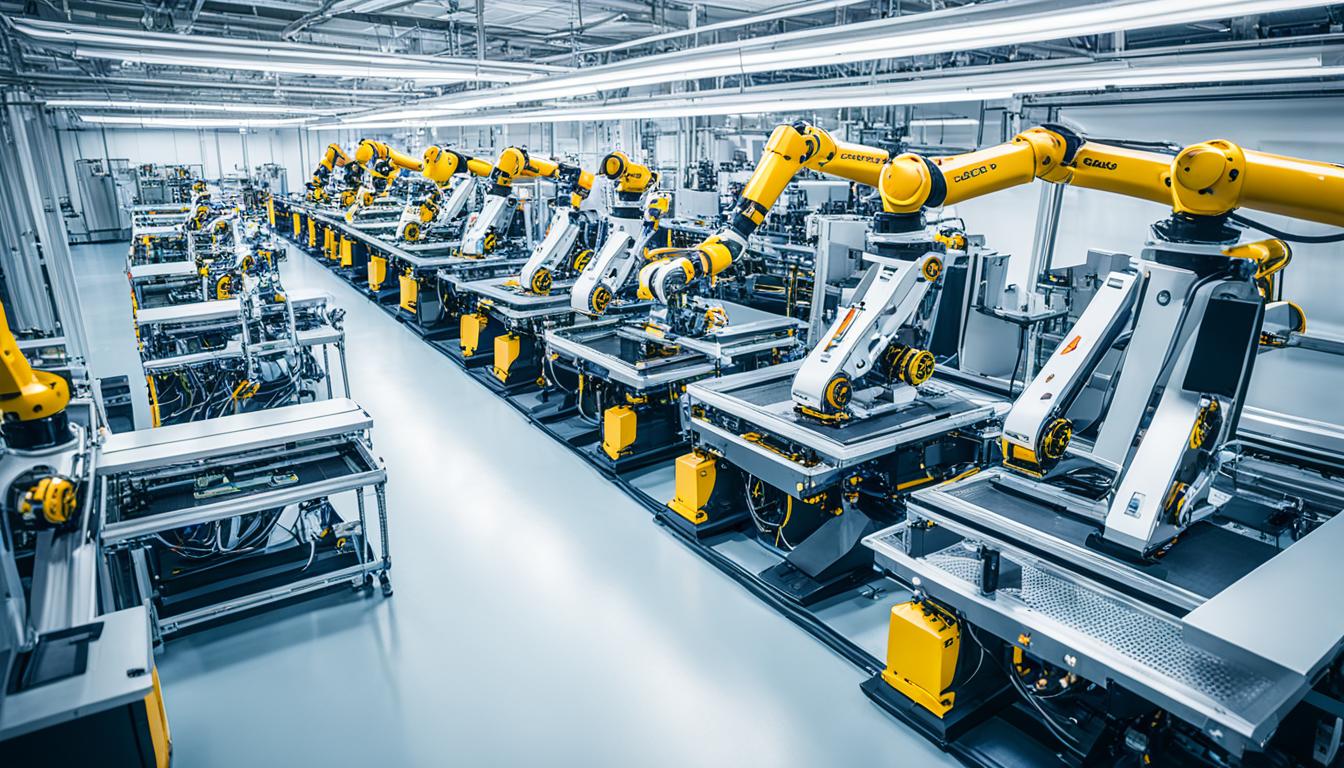

Robotics and AI are revolutionizing manufacturing safety, bringing precision and intelligent platforms to hazardous procedures and harsh environments. Modern robotic systems integrate continuous learning and improvement abilities, optimizing their actions and enhancing overall performance. With their exceptional precision, robotic systems are ideal for executing tasks that require high levels of accuracy, reducing the risk of errors and accidents.

Enhancing Safety Monitoring

AI algorithms play a critical role in safety monitoring by detecting subtle patterns and providing real-time alerts for workplace and environmental hazards. These algorithms analyze data collected from sensors and other sources, allowing workers and safety personnel to proactively address potential safety risks. By leveraging AI, manufacturers can improve safety measures and prevent accidents, enhancing the well-being of employees.

Collaboration between Robots and Humans

Robotic systems can work alongside human workers, complementing their abilities and enhancing safety in manufacturing facilities. With their precision and strength, robots can handle heavy and dangerous tasks, reducing the risk of injuries. This collaborative approach not only ensures safer working conditions but also leads to increased productivity and efficiency.

Robots equipped with workplace detection capabilities can identify the presence of humans in their vicinity, allowing them to adjust their actions and avoid collisions. This feature adds an extra layer of safety to manufacturing operations, ensuring the well-being of both humans and robots in shared workspaces.

Future Safety Enhancements

The integration of robotics and AI in manufacturing safety is an ongoing process, with continuous advancements being made to further enhance workplace safety. Future developments may include the use of advanced sensors and AI algorithms to detect and mitigate risks in real time, further reducing the occurrence of accidents and injuries.

Additionally, the adoption of intelligent platforms and autonomous systems can automate routine safety procedures, freeing up human workers to focus on more complex tasks. The combination of robotics and AI has the potential to create safer and more efficient manufacturing environments, ensuring the well-being and productivity of all personnel involved.

Green Energy

Green energy initiatives are becoming a focus in the manufacturing industry. By incorporating renewable practices into business operations, companies aim to promote sustainability, reduce waste, and conserve resources. One of the key aspects of green energy is the adoption of clean energy sources, such as solar and wind power, to scale manufacturing operations sustainably and minimize the carbon footprint.

Aside from clean energy sources, manufacturers are also implementing other sustainable practices. This includes responsible sourcing of supplies, reducing waste by-products through recycling and efficient production processes, and promoting utility conservation within their facilities. These efforts not only contribute to environmental well-being but also align with consumer demands for more responsible production practices.

To illustrate the impact of green energy initiatives, let’s take a look at how a manufacturing company has reduced its waste and conserved resources:

| Green Energy Initiatives | Results |

|---|---|

| Implementation of solar panels for energy generation | Reduction in carbon emissions and reliance on fossil fuels |

| Utilization of wind turbines for power generation | Additional clean energy source to offset electricity consumption |

| Adoption of resource conservation practices | Reduction in water usage and optimized energy consumption |

| Promotion of waste reduction and recycling | Significant decrease in landfill waste through recycling initiatives |

By incorporating green energy practices, this company has not only improved its environmental impact but also experienced cost savings and operational efficiency. The shift towards green energy is a win-win situation for manufacturers, as it not only aligns with sustainability goals but also contributes to the company’s bottom line.

Overall, green energy initiatives in the manufacturing industry promote a cleaner and more sustainable future. Through renewable practices, waste reduction, resource conservation, and the adoption of clean energy sources, manufacturers are taking proactive steps towards a greener future while meeting the evolving demands of consumers who value responsible production practices.

Digital Twins

Digital twins are virtual replicas of existing systems that enable simulations and evaluations of production processes and safety practices. By creating a digital model of equipment and systems, manufacturers can gain valuable insights and optimize their operations.

These simulations can identify potential safety risks and inform improvements in manufacturing processes. Digital twins provide a realistic environment to test and evaluate new safety measures, helping manufacturers make data-driven decisions for a safer work environment.

Supply chain visualization is another key aspect of digital twins. By simulating the entire supply chain, manufacturers can understand the impact of different variables and make informed decisions. This technology allows for better planning and execution of safety measures across the supply chain, ensuring the smooth flow of materials and reducing potential risks.

Benefits of Digital Twins in Manufacturing Safety

Digital twins offer several benefits in enhancing manufacturing safety:

- Identifying safety risks: Simulations in digital twins can identify potential safety risks and help manufacturers proactively address them.

- Optimizing safety practices: By evaluating different safety measures virtually, manufacturers can optimize their safety practices for maximum efficiency and effectiveness.

- Visualizing the supply chain: Digital twins provide a visual representation of the entire supply chain, helping manufacturers identify bottlenecks and improve safety.

- Evaluating safety procedures: Manufacturers can use digital twins to evaluate the effectiveness of safety procedures and identify areas for improvement.

- Enhancing collaboration: Digital twins facilitate collaboration between different departments and stakeholders, enabling them to collectively work towards improving manufacturing safety.

With digital twins, manufacturers can simulate real-world scenarios, iterate on safety measures, and continuously improve safety practices across their operations.

| Benefits of Digital Twins in Manufacturing Safety |

|---|

| Identifying safety risks |

| Optimizing safety practices |

| Visualizing the supply chain |

| Evaluating safety procedures |

| Enhancing collaboration |

Internet of Things (IoT)

The Internet of Things (IoT) is revolutionizing manufacturing safety by connecting devices and collecting data for risk prediction and real-time monitoring. Through interconnected devices, such as sensors, manufacturers can gather valuable data to understand worker trends, identify potential hazards, and prevent accidents. This data-driven approach enables proactive safety measures and the creation of safer work environments.

“IoT technology allows for the seamless integration of devices and systems, enabling real-time monitoring of equipment and vehicle navigation. By monitoring and analyzing this data, manufacturers can prevent collisions and identify potential risks, such as protruding objects that may cause accidents. The IoT’s ability to provide real-time insights empowers manufacturers to prioritize safety and implement effective measures.”

With the Internet of Things (IoT), manufacturers can leverage the power of interconnected devices and data collection to predict risks and improve safety in real-time. By analyzing the data gathered from sensors and other devices, manufacturers can gain valuable insights into worker behavior, potential hazards, and equipment performance. This allows for the implementation of proactive safety measures and the prevention of accidents before they occur.

Benefits of IoT in Manufacturing Safety

Implementing IoT technologies in manufacturing safety offers several benefits, including:

- Improved Risk Prediction: By collecting and analyzing data from interconnected devices, manufacturers gain a better understanding of potential safety risks and can take proactive measures to prevent accidents.

- Real-time Monitoring: IoT enables real-time monitoring of equipment and worker behavior, allowing for immediate action to be taken in case of emergencies or hazardous situations.

- Collision Prevention: Through IoT technology, manufacturers can monitor vehicle navigation and equipment movement to prevent collisions and reduce the risk of accidents in the workplace.

The integration of IoT in manufacturing safety provides manufacturers with valuable data-driven insights, empowering them to create safer work environments and reduce the occurrence of accidents.

| Benefits of IoT in Manufacturing Safety |

|---|

| Improved Risk Prediction |

| Real-time Monitoring |

| Collision Prevention |

Source: alt=”IoT in Manufacturing Safety”

Additive Manufacturing and 3D Printing

Additive manufacturing, also known as 3D printing, is revolutionizing manufacturing safety by enabling the creation of more robust and lighter parts. This innovative technology utilizes digital design and precise material arrangement to fabricate objects, eliminating the need for traditional manufacturing methods that involve removing material. By building objects layer by layer, 3D printing allows for greater design flexibility and customization, leading to safer and more efficient production processes.

One of the key advantages of additive manufacturing is the ability to produce robust and lightweight parts. Traditional manufacturing techniques often rely on bulky components, which can contribute to increased weight and potential safety hazards. In contrast, 3D printing enables the production of complex geometries and optimized structures, resulting in lighter parts without compromising strength or durability.

With digital design at the core of additive manufacturing, manufacturers can leverage this technology to optimize safety in their production processes. Digital design software allows for precise customization of parts, incorporating safety features, such as ergonomic designs or reinforced areas, to enhance worker safety. By utilizing digital design tools, manufacturers can also simulate and evaluate safety aspects before final production, ensuring that safety requirements are met.

Additive manufacturing has cost-effective applications across various industries, contributing to improved manufacturing safety. The ability to produce parts on-demand and in-house eliminates the need for complex supply chains, reducing the risk of delays and ensuring a timely response to safety-related issues. Additionally, 3D printing enables rapid prototyping, allowing manufacturers to test and iterate safety improvements quickly and efficiently.

As additive manufacturing technologies continue to advance, so does the potential for enhancing manufacturing safety. The combination of robust and lighter parts, digital design capabilities, cost-effective applications, and rapid prototyping makes additive manufacturing a powerful tool for improving safety in manufacturing processes.

Moreover, the integration of additive manufacturing with other emerging technologies, such as robotics, AI, and IoT, opens up new possibilities for enhancing safety in manufacturing environments. These technologies can work together synergistically to automate the production of safety-critical components and enable real-time monitoring of equipment and worker safety.

By leveraging the benefits of additive manufacturing, manufacturers can optimize design, production processes, and safety measures, ultimately creating safer work environments for employees. The adoption of additive manufacturing and 3D printing paves the way for a future where safety, efficiency, and innovation go hand in hand.

Advanced Automation and Robotics

Advanced automation and robotics are driving a paradigm shift in manufacturing safety, ushering in a new era of collaborative environments and reducing reliance on human intervention. This holds particular significance in the context of labor shortages and the need for improved productivity and accuracy.

The integration of autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) is revolutionizing manufacturing and warehousing facilities. AMRs leverage advanced navigation technology to study the facility layout and identify the most efficient routes to transport goods. On the other hand, AGVs follow pre-defined routes to streamline material handling processes.

These cutting-edge technologies have far-reaching benefits for manufacturing safety. By automating repetitive and physically demanding tasks, AMRs and AGVs minimize the risk of human errors and accidents. They also enhance efficiency by optimizing workflows and reducing production delays.

Furthermore, the implementation of advanced automation and robotics results in safer collaborative environments. By working alongside humans, these intelligent machines provide additional support and augment their capabilities, resulting in improved safety outcomes.

Benefits of Advanced Automation and Robotics:

- Enhanced productivity through optimized workflows

- Improved accuracy in material handling and production processes

- Reduction in labor shortages and heavy material handling challenges

- Minimization of human errors and accidents in hazardous environments

- Creation of safer and more collaborative work environments

As the manufacturing industry continues to evolve, the adoption of advanced automation and robotics is essential for companies aiming to stay competitive and mitigate potential safety risks. By embracing these cutting-edge technologies, manufacturers can achieve higher levels of productivity, efficiency, and safety in their operations.

Comparison of Advanced Automation and Robotics Technologies

| Technology | Key Features | Benefits |

|---|---|---|

| Autonomous Mobile Robots (AMRs) | Advanced navigation technology Intelligent decision-making capabilities | Optimized material transportation Increased efficiency and accuracy Enhanced workplace safety |

| Automated Guided Vehicles (AGVs) | Follow pre-defined routes Integration with warehouse management systems | Streamlined material handling processes Reduced manual labor and associated risks Improved production workflow |

Working with Wearables

Wearable technology is revolutionizing manufacturing safety by enabling advanced environmental monitoring and health analytics. By integrating sensors into wearable devices like smartwatches, jackets, and helmets, manufacturers can monitor key health indicators and detect fatigue, stress, and strain in workers. This data provides supervisors with valuable insights to take preventive action and improve workplace safety.

In addition to health monitoring, wearables enhance situational awareness in dynamic manufacturing environments. They provide real-time updates on potential hazards, allowing workers to stay alert and make informed decisions. This situational awareness is crucial for accident prevention and creating safer work environments.

Furthermore, wearables can be utilized for hands-free training, eliminating the need for traditional training materials and minimizing distractions. Workers can access training materials, instructions, and safety protocols directly through their wearables, ensuring they have the necessary information at their fingertips. This not only improves worker performance but also reduces the risk of injuries caused by distractions or improper procedures.

The Benefits of Working with Wearables:

- Improved environmental monitoring

- Enhanced health analytics

- Fatigue detection and prevention

- Real-time situational awareness

- Hands-free training and information access

Wearables are transforming manufacturing safety by leveraging technology to empower workers, enhance safety measures, and create efficient workflows. With the ability to monitor health, provide real-time updates, and offer hands-free training, wearables are a vital component in creating a safer and more productive manufacturing environment.

| Wearable Technology | Benefits |

|---|---|

| Smartwatches | Monitor health indicators |

| Jackets | Detect fatigue and strain |

| Helmets | Provide real-time situational awareness |

Conclusion

The manufacturing industry is at the forefront of technological advancement, particularly in the realm of safety. Trends such as industrial automation, digitization, robotics, and the integration of IoT and AI are transforming manufacturing safety practices. These trends offer numerous benefits, including improved data collection and analysis, real-time monitoring, predictive maintenance, enhanced efficiency, and most importantly, the creation of safer work environments for employees.

By embracing these future trends, manufacturers can stay competitive and ensure the well-being of their workforce. The use of advanced technologies allows for accurate and continuous monitoring of safety conditions, enabling proactive measures to prevent accidents. Predictive maintenance techniques help identify potential issues before they become major hazards, reducing downtime and ensuring smooth operations.

The integration of robotics and AI enables precision and intelligence in manufacturing processes, minimizing risks associated with hazardous procedures. Additionally, the application of IoT and AI in safety monitoring provides valuable insights into workplace conditions, helping identify potential hazards and preventing accidents. Digitization and automation streamline safety procedures, allowing workers to focus on critical tasks and ensuring compliance with safety protocols.

As the manufacturing industry continues to evolve, it is essential for manufacturers to adapt and embrace these advancements. By doing so, they can enhance safety practices, mitigate risks, and optimize productivity. Prioritizing the well-being of employees not only safeguards their physical health but also fosters a positive work environment. Ultimately, by embracing these future trends, manufacturers can create a safer and more sustainable future for the industry as a whole.

FAQ

What are the future trends in manufacturing safety?

The future trends in manufacturing safety include industrial automation, workplace safety technology, predictive maintenance in manufacturing, smart manufacturing solutions, digital transformation in safety management, AI in manufacturing safety, IoT applications in safety monitoring, and machine learning for occupational safety.

How is 5G and edge computing transforming the manufacturing industry?

5G and edge computing enable faster and more reliable wireless connectivity, seamless data transfer, and remote monitoring in manufacturing. This technology allows for real-time data gathering and analysis, safety sensor detection, and immediate actions in hazardous environments.

How does digitization and automation revolutionize manufacturing safety?

Digitization and automation enable data gathering and automated processes, improving safety procedures and accuracy in monitoring. It reduces manual work, enhances maintenance schedules and safety shut-off procedures, improving overall safety in manufacturing facilities.

What role do robotics and AI play in manufacturing safety?

Robotics and AI enhance manufacturing safety through precise and continuous learning robotic systems. They optimize actions, detect workplace and environmental hazards, and work alongside humans, increasing overall safety in manufacturing facilities.

How do green energy initiatives contribute to manufacturing safety?

Green energy initiatives reduce waste, conserve resources, and promote sustainability in manufacturing. Adopting renewable practices, such as solar and wind power, can scale operations sustainably, reduce carbon footprints, and align with consumer demands for responsible production.

How do digital twins enhance manufacturing safety?

Digital twins create virtual replicas of systems to simulate and evaluate production processes and safety practices. They identify potential safety risks, optimize operations, visualize and simulate supply chains, and enable better safety planning and execution in manufacturing facilities.

How is the Internet of Things (IoT) revolutionizing manufacturing safety?

IoT connects devices and collects data for risk prediction and real-time monitoring in manufacturing. Interconnected sensors gather data to understand worker trends, identify hazards, prevent accidents, monitor equipment, and prevent collisions, creating safer work environments through data-driven insights.

How does additive manufacturing and 3D printing transform manufacturing safety?

Additive manufacturing and 3D printing enable the creation of robust and lighter parts, reducing the need for traditional manufacturing methods. It improves safety by creating customized parts and optimizing designs, leading to safer and more efficient production processes.

How do advanced automation and robotics transform manufacturing safety?

Advanced automation and robotics create collaborative environments and reduce reliance on human intervention. Autonomous mobile robots and automated guided vehicles enhance efficiency, accuracy, and safety, particularly in cases of labor shortages and heavy material handling.

How does working with wearables enhance manufacturing safety?

Wearables monitor environmental conditions and workers’ health analytics, detecting fatigue, stress, and strain. They enable preventive action, improve situational awareness, provide real-time updates, and enhance worker performance, reducing the risk of injuries in dynamic manufacturing environments.

What are the future trends in manufacturing safety?

The manufacturing industry is experiencing significant advancements in safety technology. These trends, such as industrial automation, digitization, robotics, and the integration of IoT and AI, revolutionize manufacturing safety by improving data collection, analysis, and real-time monitoring. They enable predictive maintenance, enhance efficiency, and create safer work environments for employees.