Step 1: Digital Transformation in Procurement

The Importance of Digital Transformation in Procurement

Manual processes and limited visibility often plague traditional procurement. Digital transformation offers a refreshing approach. By automating tasks, harnessing data insights, and fostering stronger supplier relationships, organizations can significantly enhance efficiency, reduce costs, and improve overall supply chain performance.

Key Technologies Driving Procurement Transformation

Procurement automation revolutionizes operations by streamlining routine tasks. Spend analysis uncovers hidden cost savings through data-driven insights. Supplier Relationship Management (SRM) cultivates stronger partnerships, and e-procurement simplifies purchasing through online platforms.

Implementing a Digital Procurement Strategy

Success in digital procurement begins with a well-defined roadmap that outlines goals and implementation phases. Gaining employee buy-in is crucial, requiring effective change management and training. Carefully selecting and integrating the right procurement software ensures a smooth transition and maximizes the benefits of digital transformation.

Step 2: Risk Management in Procurement

Identifying and Assessing Procurement Risks

Effective procurement demands a keen awareness of potential risks. From supply chain disruptions to quality issues and financial uncertainties, a comprehensive understanding of these challenges is crucial. By employing robust risk assessment methodologies, organizations can proactively identify vulnerabilities and prioritize mitigation efforts.

Risk Mitigation Strategies

Building a resilient supply chain requires proactive risk management. Diversifying supplier base, developing comprehensive contingency plans, and securing appropriate insurance coverage are essential strategies. By implementing these measures, organizations can safeguard against potential disruptions and minimize their impact.

Risk Monitoring and Response

Continuous monitoring of supply chain risks is vital. Establishing early warning systems and key performance indicators (KPIs) helps identify emerging threats. Furthermore, well-crafted crisis management plans ensure a swift and effective response to unforeseen challenges.

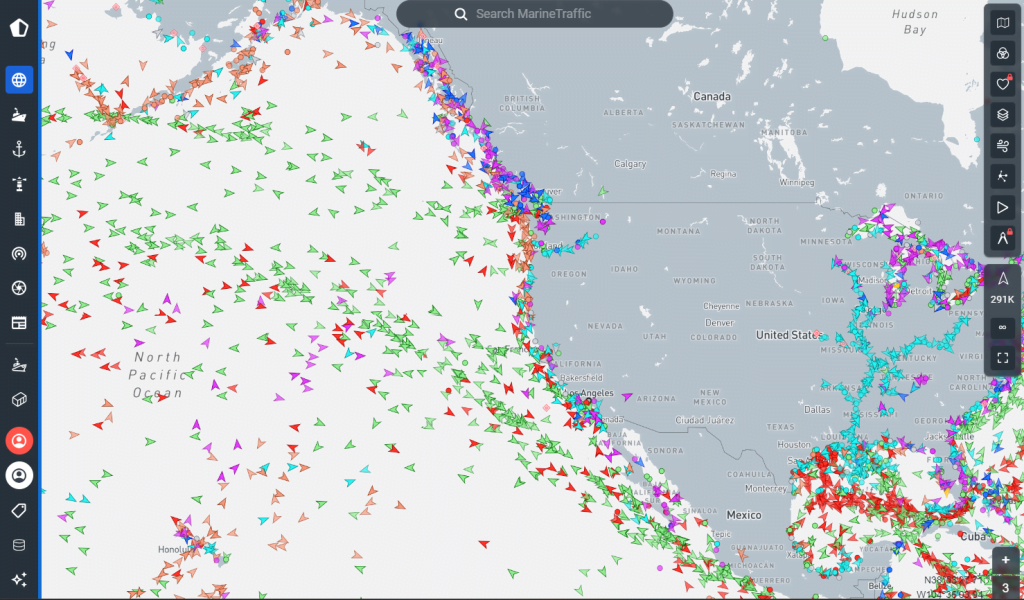

Step 3: Supply Chain Visibility

Effective procurement hinges on clear visibility into the supply chain. Real-time data and advanced analytics empower organizations to make informed decisions, optimize inventory levels, and enhance overall supply chain performance. By leveraging technology and establishing robust data management practices, businesses can gain valuable insights and mitigate potential disruptions.

Understanding the Importance of Data

Effective supply chain visibility hinges on robust data collection and analysis. By harnessing the power of data, organizations can gain real-time insights into inventory levels, production schedules, and transportation routes. This information is crucial for optimizing operations, reducing costs, and preventing disruptions.

Leveraging Technology for Enhanced Visibility

Technology plays a pivotal role in achieving supply chain visibility. Advanced solutions such as supply chain management software, Internet of Things (IoT) sensors, and data analytics platforms empower businesses to track shipments, monitor inventory levels, and identify potential bottlenecks. By integrating these tools, organizations can create a connected and transparent supply chain.

Building Strong Supplier Relationships

Collaboration with suppliers is essential for improving supply chain visibility. By fostering open communication and data sharing, organizations can gain valuable insights into supplier operations, performance, and potential risks. Implementing supplier portals and performance management systems can further strengthen these partnerships and enhance visibility.

Step 4: Supply Chain Sustainability

Sustainability is no longer an option but a necessity for forward-thinking organizations. Integrating environmental and social responsibility into the procurement process is crucial. By prioritizing ethical sourcing, reducing carbon footprints, and minimizing waste, businesses can enhance their reputation, attract eco-conscious customers, and contribute to a more sustainable future.

Prioritizing Ethical Sourcing

A sustainable supply chain begins with ethical sourcing practices. This involves ensuring that products are produced and sourced in a responsible manner, respecting human rights, labor standards, and environmental regulations. By conducting thorough supplier audits and certifications, organizations can mitigate risks and build trust with consumers.

Reducing Environmental Impact

Minimizing the environmental footprint is a cornerstone of sustainability. Implementing eco-friendly practices throughout the supply chain, such as reducing waste, optimizing transportation, and using renewable energy, can significantly contribute to sustainability goals. Additionally, adopting circular economy principles can help conserve resources and reduce waste.

Measuring and Reporting Sustainability Performance

Tracking and reporting sustainability metrics is essential for measuring progress and identifying areas for improvement. Key performance indicators (KPIs) such as carbon emissions, waste reduction, and supplier compliance can help organizations assess their sustainability performance. Transparent communication of sustainability efforts can also enhance brand reputation and attract environmentally conscious customers.

Step 5: Collaboration and Partnership

A successful supply chain thrives on strong collaboration among all stakeholders. By fostering open communication, shared goals, and mutual trust, organizations can optimize performance, reduce costs, and enhance innovation. Effective collaboration involves sharing information, aligning strategies, and working together to overcome challenges. Building long-term partnerships with suppliers, customers, and other key stakeholders is essential for creating a resilient and competitive supply chain.

For 18+ years, Long Shen has been a dedicated partner to US businesses, successfully developing products that meet and exceed expectations. Our collaborative approach ensures your vision comes to life.

A thriving supply chain is built on strong, collaborative relationships. By fostering open communication, shared objectives, and mutual trust, we can optimize performance, reduce costs, and drive innovation.

Our collaborative approach involves:

- Open Dialogue: We believe in the power of open communication. We share information, insights, and challenges transparently to build a foundation of trust and understanding.

- Shared Goals: Our success is intertwined with yours. We align our objectives to ensure that we are working towards the same end goal.

- Mutual Benefits: Collaboration is a two-way street. We strive to create partnerships where everyone benefits, leading to long-term success.

By working closely with our clients, we build strong, enduring partnerships that drive results. Together, we overcome challenges, identify opportunities, and create innovative solutions.

Collaboration offers numerous benefits, including:

- Increased Efficiency: By pooling resources and expertise, we streamline processes, reduce errors, and accelerate project timelines.

- Enhanced Innovation: Diverse perspectives and shared knowledge foster creativity and lead to groundbreaking product development.

- Improved Problem-Solving: Collaborative problem-solving generates innovative solutions that address complex challenges.

- Risk Mitigation: By sharing information and working together, we can identify and mitigate potential risks more effectively.

- Stronger Relationships: Collaborative partnerships build trust, loyalty, and long-term commitment.

We are committed to building strong partnerships based on mutual respect, open communication, and a shared vision for success.